What Is a Wet Load in Autoclaving?

A wet load refers to a condition where sterilized

instruments, packs, trays, or wraps remain wet after completion of the

autoclave cycle, including the drying phase.

Examples of wet loads:

- Condensation

inside instrument trays

- Damp

linen packs

- Moist

paper-plastic pouches

- Water

droplets on rigid containers

According to sterilization standards, any moisture on

sterilized items renders them non-sterile, regardless of whether the exposure

phase was successful.

In this comprehensive guide from Aarogyaa Bharat, we

explain:

- What

wet loads are

- Why

they occur

- How

to diagnose root causes

- Why

wet loads are unsafe

- Step-by-step

prevention strategies

- Best

practices for hospitals and CSSD units

Why Wet Loads Are a Serious Problem (Not Just Cosmetic)

Wet loads are not acceptable in healthcare sterilization for

the following reasons:

1. Loss of Sterility

Moisture allows microorganisms to wick through packaging,

breaking the sterile barrier.

2. Increased Infection Risk

Wet instruments increase the risk of:

- Surgical

Site Infections (SSIs)

- Post-operative

complications

- Cross-contamination

3. Non-Compliance With Standards

Wet loads violate:

- AAMI

ST79

- CDC

infection control guidelines

- NABH

& JCI requirements

4. Costly Reprocessing

All wet items must be:

- Quarantined

- Re-cleaned

- Re-sterilized

This leads to workflow delays, overtime costs, and OT scheduling disruptions.

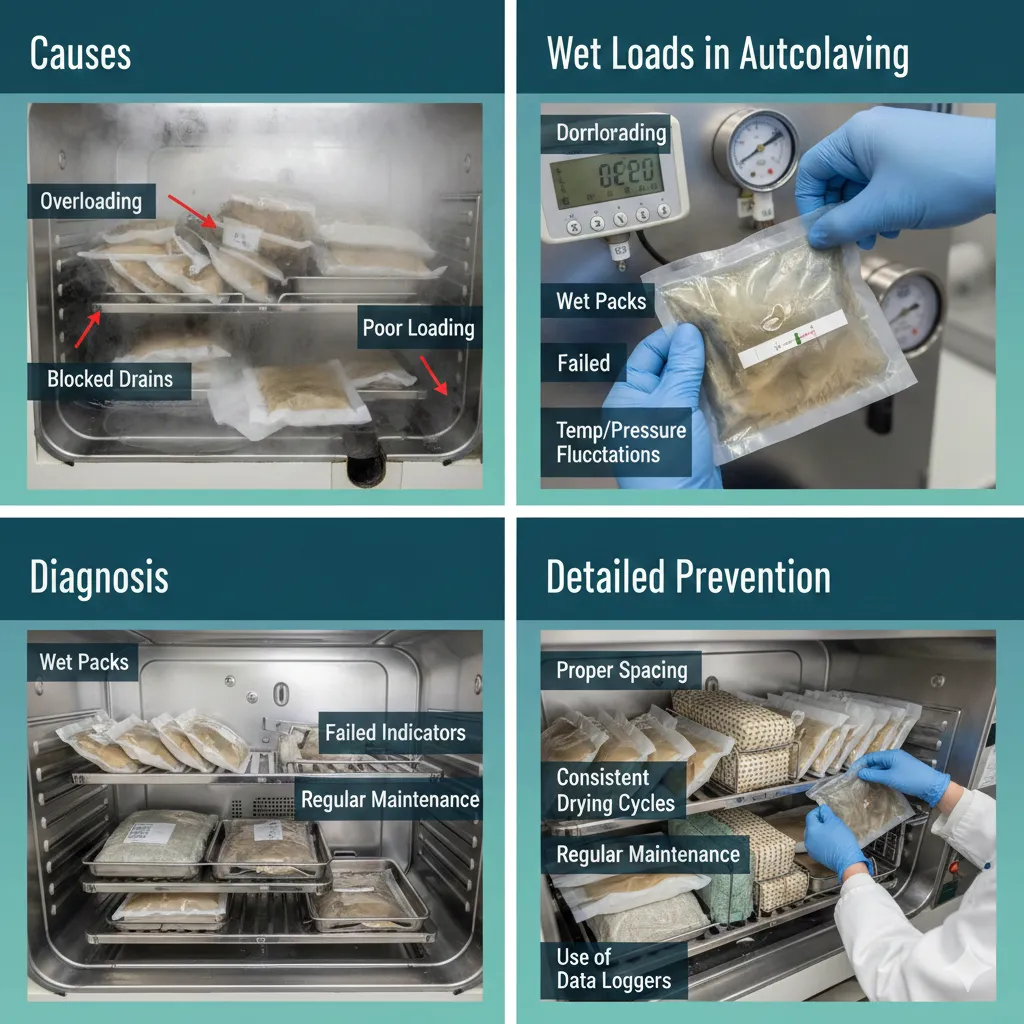

Common Causes of Wet Loads in Autoclaves

Wet loads almost never have a single cause. They typically

result from a combination of equipment, loading, packaging, and process issues.

1. Improper Loading of the Autoclave

Incorrect loading is the most frequent cause of wet loads.

Common loading errors:

- Overloading

the chamber

- Stacking

trays too tightly

- Placing

heavy metal trays above lighter packs

- Blocking

air removal pathways

Why this causes wet loads:

Steam cannot circulate properly, and trapped air prevents effective drying.

Best practice:

- Maintain

space between trays

- Follow

manufacturer-recommended load configurations

- Avoid

mixing heavy and light items inappropriately

2. Incorrect Packaging Materials or Techniques

Packaging plays a critical role in moisture retention.

Common packaging issues:

- Using

low-quality wraps

- Over-wrapping

instrument sets

- Sealing

pouches incorrectly

- Using

damaged or expired packaging

Why this causes wet loads:

Poor packaging traps moisture or prevents proper evaporation during drying.

Best practice:

- Use

validated sterilization wraps and pouches

- Avoid

excessive layers

- Ensure

seals are intact and breathable

3. Excessive Instrument Weight or Tray Density

Heavy instrument sets - especially orthopaedic or robotic

trays - are notorious for causing wet loads.

Typical problems:

- Dense

metal mass retains heat and moisture

- Inadequate

drying time for heavy loads

Why this causes wet loads:

Metal cools unevenly, causing condensation when chamber pressure drops.

Best practice:

- Use

extended dry times for heavy sets

- Break

large sets into smaller trays when possible

4. Inadequate Drying Phase Settings

Autoclave drying parameters are often misconfigured.

Drying issues include:

- Drying

time too short

- Insufficient

vacuum pulses

- Faulty

vacuum pump performance

Why this causes wet loads:

Moisture is not fully evacuated from packs before cycle completion.

Best practice:

- Validate

drying time based on load type

- Regularly

test vacuum efficiency

Steam quality is a hidden but critical factor.

Steam issues include:

- Excess

moisture (wet steam)

- Non-condensable

gases

- Contaminants

from boiler systems

Why this causes wet loads:

Wet steam introduces additional moisture that drying systems cannot fully

remove.

Best practice:

- Monitor

steam quality regularly

- Ensure

boiler maintenance and filtration

6. Autoclave Mechanical or Maintenance Issues

Faulty equipment often leads to persistent wet loads.

Common equipment problems:

- Leaking

door gaskets

- Malfunctioning

vacuum pumps

- Blocked

drain lines

- Faulty

temperature or pressure sensors

Why this causes wet loads:

Autoclave cannot achieve proper vacuum or pressure differentials for drying.

Best practice:

- Schedule

preventive maintenance

- Investigate

repeated wet load incidents immediately

How to Diagnose Wet Loads (Root Cause Analysis)

When a wet load occurs, do not ignore it. Follow a

structured diagnostic approach.

Step-by-Step Diagnosis Checklist

- Stop

distribution immediately

- Do

not release wet items

- Review

cycle printouts

- Temperature

- Pressure

- Drying

time

- Inspect

loading pattern

- Overloading

- Tray

placement

- Check

packaging integrity

- Wrap

damage

- Pouch

seals

- Assess

equipment performance

- Vacuum

test

- Bowie-Dick

test

- Document

findings

- Required

for NABH & infection control audits

What To Do If a Wet Load Is Found

Immediate Actions:

- Quarantine

the entire load

- Label

as “NOT STERILE”

- Inform

CSSD supervisor or infection control team

Reprocessing Protocol:

- Open

packs

- Re-clean

instruments if required

- Re-package

using correct materials

- Re-sterilize

with corrected parameters

Never attempt to air-dry or towel-dry wet sterile items.

Detailed Prevention Strategies for Wet Loads

1. Standardize Loading Protocols

- Train

staff using visual load diagrams

- Separate

heavy and light loads

2. Optimize Packaging Selection

- Use

breathable, validated wraps

- Avoid

over-packing trays

3. Validate Sterilization Cycles

- Different

cycles for:

- Linen

- Instruments

- Heavy

orthopaedic trays

4. Improve Staff Training

- Continuous

CSSD education

- Annual

competency assessments

5. Strengthen Equipment Maintenance

- Scheduled

preventive maintenance

- Immediate

investigation of repeat failures

6. Monitor with Quality Indicators

- Wet

load incident tracking

- Cycle

failure trend analysis

Compliance With Standards & Guidelines

Wet load prevention is mandated by:

- AAMI

ST79 – Steam sterilization standards

- CDC

Guidelines – Infection control

- NABH

/ JCI – Accreditation requirements

Failure to address wet loads can result in:

- Non-compliance

findings

- Patient

safety incidents

- Accreditation

risks

How Aarogyaa Bharat Supports Safe Sterilization Practices

At Aarogyaa Bharat, we support hospitals and CSSD units

with:

- High-quality

autoclaves

- Sterilization

accessories & consumables

- Expert

guidance on equipment selection

- Training-aligned

equipment solutions

Our focus is patient safety, compliance, and operational

efficiency.

Frequently Asked Questions (FAQs)

Q1. Is a wet load considered sterile?

No. Any moisture invalidates sterility and the load must be reprocessed.

Q2. Can wet loads be air-dried and reused?

No. Air-drying does not restore sterility.

Q3. Are wet loads caused only by equipment failure?

No. Loading, packaging, steam quality, and cycle selection are equally

responsible.

Q4. How often should autoclaves be tested for drying

efficiency?

Regularly, especially after maintenance or cycle modifications.

Conclusion

Wet loads in autoclaving are preventable failures - not

unavoidable accidents. By understanding their causes, diagnosing them

correctly, and implementing structured prevention strategies, hospitals can

protect patients, maintain compliance, and improve CSSD efficiency.

In sterilization, dry means safe. Anything less is a risk.