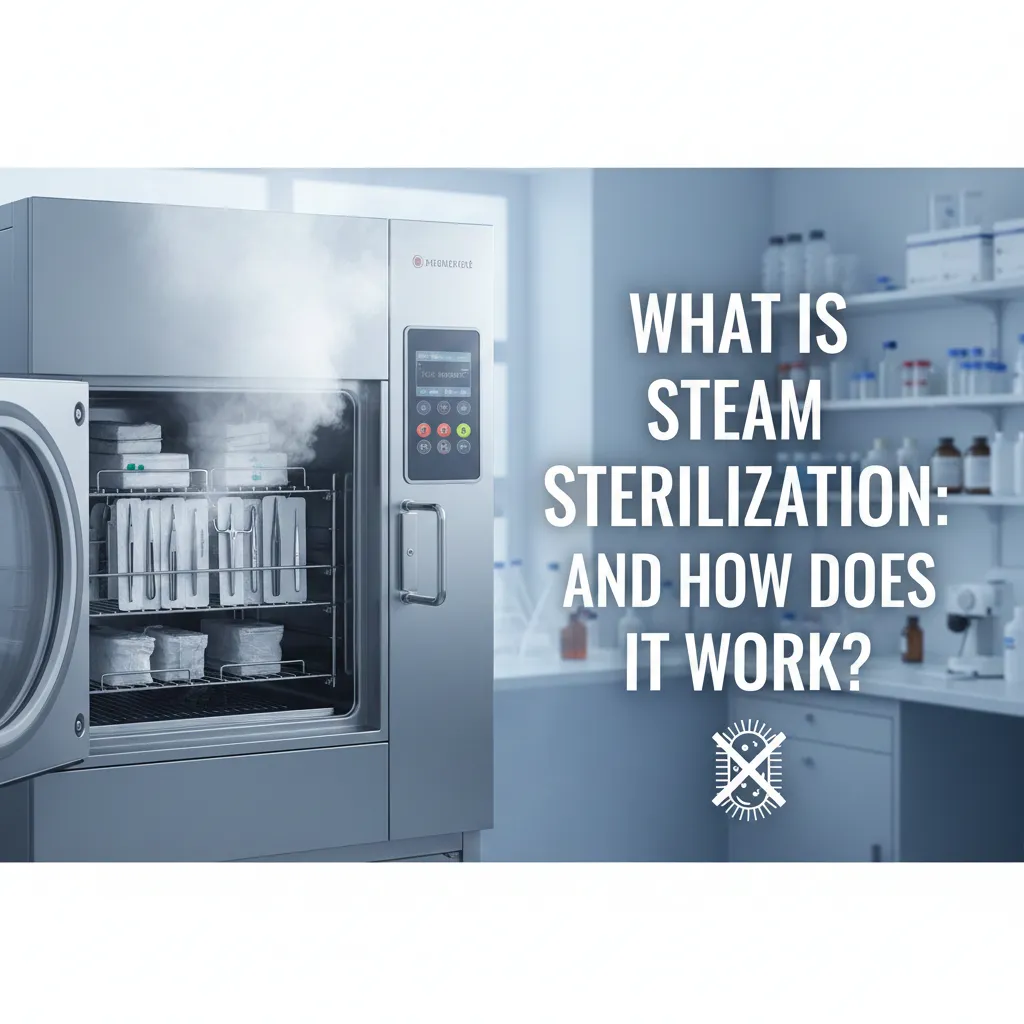

What Is Steam Sterilization?

Steam sterilization is a moist heat sterilization process

that uses saturated steam at temperatures between 121°C and 134°C, under

controlled pressure, to eliminate all forms of microorganisms, including:

- Bacteria

- Viruses

- Fungi

- Mycobacteria

- Bacterial

spores (most resistant)

The process is performed using a steam sterilizer, commonly

called an autoclave.

Once an item completes a validated steam sterilization

cycle, it is considered completely sterile, meaning no viable microorganisms

remain.

This guide by Aarogyaa Bharat explains:

- What

steam sterilization is

- How

steam sterilization works

- Temperature

and pressure requirements

- Types

of steam sterilizers (autoclaves)

- Applications,

advantages, and limitations

- Best

practices for safe and effective sterilization

Why Steam Sterilization Is Preferred in Healthcare

Steam sterilization remains the first choice in healthcare

because it is:

- Highly

effective against all microorganisms

- Fast

compared to chemical methods

- Non-toxic

and residue-free

- Environmentally

friendly

- Easy

to monitor and validate

- Cost-effective

for high-volume use

Because of these benefits, steam sterilization is widely

used in:

- Hospitals

and operation theatres

- Central

Sterile Supply Departments (CSSD)

- Diagnostic

and research laboratories

- Pharmaceutical

manufacturing

- Dental

and veterinary clinics

How Does Steam Sterilization Work?

Steam sterilization works by transferring heat energy from

saturated steam to microorganisms, causing irreversible damage to their

cellular structure.

Step-by-Step Process

1. Air Removal

Air is removed from the chamber using gravity displacement

or vacuum systems.

This is critical because air prevents effective steam penetration.

2. Steam Admission

Saturated steam fills the chamber and contacts all exposed

surfaces.

3. Exposure Phase

Items are held at a specific temperature and pressure for a

defined time, ensuring complete microbial destruction.

Common parameters:

- 121°C

at ~15 psi for 15-30 minutes

- 132-134°C

at ~27-30 psi for 3-10 minutes

4. Microbial Destruction

High heat causes:

- Protein

denaturation

- Enzyme

inactivation

- Cell

membrane rupture

This destroys even highly resistant bacterial spores.

5. Exhaust and Drying

Steam is exhausted and moisture is removed to prevent wet

loads and recontamination.

Temperature and Pressure in Steam Sterilization

|

Temperature |

Pressure |

Typical

Applications |

|

121°C |

~15 psi |

Culture

media, liquids, linen |

|

132°C |

~27 psi |

Surgical

instruments |

|

134°C |

~30 psi |

Wrapped CSSD

instrument sets |

Higher temperatures require shorter exposure times.

Types of Steam Sterilizers (Autoclaves)

1. Gravity Displacement Autoclave

- Steam

displaces air naturally

- Suitable

for simple, unwrapped loads and liquids

Used in:

Laboratories, basic medical settings

2. Pre-Vacuum (High-Vacuum) Autoclave

- Uses

vacuum pumps to remove air

- Provides

excellent steam penetration

- Ideal

for wrapped and porous loads

Used in:

Hospitals, CSSD, operation theatres

3. Tabletop / Benchtop Autoclave

- Compact

design

- Suitable

for small practices

Used in:

Dental clinics, small labs, outpatient centres

Items Commonly Sterilized Using Steam

Steam sterilization is ideal for heat- and

moisture-resistant items, including:

- Surgical

instruments

- Linen

packs and drapes

- Stainless

steel tools

- Glassware

- Culture

media

Not suitable for:

- Heat-sensitive

plastics

- Electronic

devices

- Moisture-sensitive

materials

Advantages of Steam Sterilization

- Kills all microorganisms including spores

- Rapid and highly reliable

- No toxic residues

- Environmentally safe

- Easy validation using indicators

- Low operational cost

Limitations of Steam Sterilization

- Not suitable for heat-sensitive items

- Requires correct loading and packaging

- Wet loads may occur if drying is inadequate

- Needs trained personnel and maintenance

These risks can be minimized with proper procedures and training.

Monitoring Steam Sterilization Effectiveness

To ensure safety and compliance:

- Chemical

indicators - confirm exposure

- Biological

indicators - confirm microbial kill

- Physical

monitoring - time, temperature, pressure records

No load should be released without verifying indicator

results.

Best Practices for Effective Steam Sterilization

- Clean

items thoroughly before sterilization

- Use

validated packaging materials

- Load

autoclaves correctly

- Select

appropriate cycle parameters

- Allow

proper drying time

- Maintain

sterilization records

- Train

staff regularly

How Aarogyaa Bharat Supports Steam Sterilization

At Aarogyaa Bharat, we support healthcare and laboratory

facilities with:

- Steam

autoclaves for hospitals and labs

- Sterilization

accessories and consumables

- CSSD-friendly

equipment solutions

- Expert

guidance on sterilization workflows

Our focus is safe, compliant, and efficient infection

control.

FAQs

Q1. Does steam sterilization kill spores?

Yes, steam sterilization destroys bacterial spores.

Q2. Why is pressure required in steam sterilization?

Pressure allows steam to reach higher temperatures safely.

Q3. What is the most common steam sterilization

temperature?

121°C and 134°C are the most commonly used.

Conclusion

Steam sterilization remains the most dependable and

effective sterilization method in healthcare and laboratory environments. When

carried out correctly - with proper cleaning, loading, cycle selection, and

monitoring - it ensures complete microbial elimination and maximum patient

safety.

In sterilization, steam continues to set the global

standard.

- Sterilization

= zero microorganisms

- Disinfection

= reduced microorganisms

Understanding this difference ensures safer healthcare

environments and better clinical outcomes in 2025 and beyond.